The Hottest New Material is… Wood

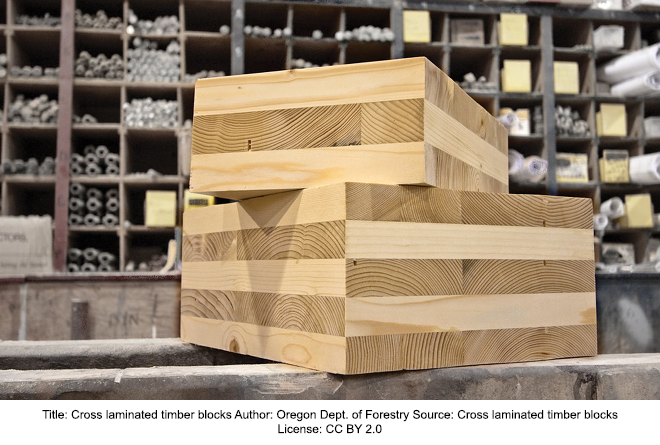

Before architecture, I had the opportunity to build almost everything from cabinets to tables to sculptural pieces of furniture. That experience of building and understanding a material so intimately gave me insight into joints and how things come together. All of this has led to my growing fascination with cross-laminated timber (CLT), almost as if I’m putting down the Lincoln Log set again and trading up for power tools. CLT’s ability to be prefabricated and assembled sheet by sheet with a crane gives me a reminiscent feeling of assembling cabinets from sheets of plywood, CLT’s much smaller cousin. A panel of CLT is composed typically of three to nine layers of lumber boards stacked in alternating directions and glued together to form a solid panel.

CLT is not necessarily a new building material rather a traditional material given new life and breadth. With the ever-increasing concern over carbon and ways to reduce the carbon footprint within the building sector, CLT could be a viable solution for single-family homes to high-rise timber buildings due to its modularity and natural carbon sequestering properties.

Similar to working with standard sheets of lumber for cabinetry and furniture making, construction with CLT panels can be thought of in a similar fashion. A minimization of framing and on-site construction contributes to both time and labor being reduced because CLT is a factory produced material improving quality control and reducing waste during the construction process. Walls with certain design profiles can be cut to shape along with accommodating MEP placement on panels through factory produced routs for electrical conduit, plumbing pipes, and mechanical chases all happening off-site minimizing construction time. To some, the modularity of this material might seem constraining, however, the possibilities are vast.

Not only is CLT a sustainable building material, but its recent update to the International Building Code (IBC) of 2021 will allow the material to spread its roots. CLT buildings will be categorized into three branches Type-IV A, Type-IV B, and Type-IV C. The primary difference between the three types is the amount of exposed timber per the occupant load causing shifts in the final allowable building height. Type-IV A being the tallest of the bunch with an allowable building height of 270 feet above grade or 18 stories. Type-IV B rests at 180 feet above grade or 12 stories with approximately 30 to 40 percent of the timber exposed. Type-IV C having the most timber exposed maxes out at 85 feet above grade or six to nine stories depending on the occupancies being an assembly or residential. When it comes to fire protection, Alcohol, Tobacco, Firearms, and Explosives (ATF) performed fire testing on wall and floor assemblies both exposed and covered with noncombustible materials where the results showed a 3-hour fire-resistance rating and a limited 5-hour rating with multiple layers of noncombustible protection added.

While my experience in woodworking has jumpstarted my interest in the material of cross-laminated timber, I see it growing in popularity among designers and builders due to its innate materiality and efficient constructability. These recent updates to the IBC allow the possibility for CLT to become a mainstream building material.

Leave a Reply